Distillation Techniques in Texas Whiskey

Texas whiskey has carved a distinct niche in the world of spirits, renowned for its bold flavors and unique character. The state’s diverse climate and innovative distillation techniques contribute to the exceptional quality of Texas whiskey. In this article, we will delve into the various distillation methods employed by Texas distilleries, including traditional and modern approaches, as well as the unique techniques that give Texas whiskey its signature taste.

Traditional Methods

Traditional distillation methods form the foundation of whiskey production, ensuring consistency and quality while maintaining time-honored practices.

Copper Pot Stills

Copper pot stills are a staple in traditional whiskey distillation, prized for their ability to enhance the flavor profile of the spirit. These stills, typically handcrafted from copper, play a crucial role in removing impurities and creating a smooth, rich whiskey. The copper material reacts with the distillate, removing sulfur compounds and other undesirable elements, resulting in a cleaner and more refined product.

In Texas, many distilleries continue to use copper pot stills, honoring the traditional methods while adding their unique twist. The use of these stills allows distillers to craft small batches with precise control over the distillation process, ensuring each bottle reflects the distillery’s unique style.

Distillation Steps

The distillation process in copper pot stills involves several key steps, each contributing to the final product’s quality:

- Mashing: The process begins with mashing, where grains such as corn, barley, and rye are mixed with water and heated to convert starches into fermentable sugars.

- Fermentation: The mash is then transferred to fermentation tanks, where yeast is added to convert sugars into alcohol. This stage typically lasts several days, resulting in a “wash” with a low alcohol content.

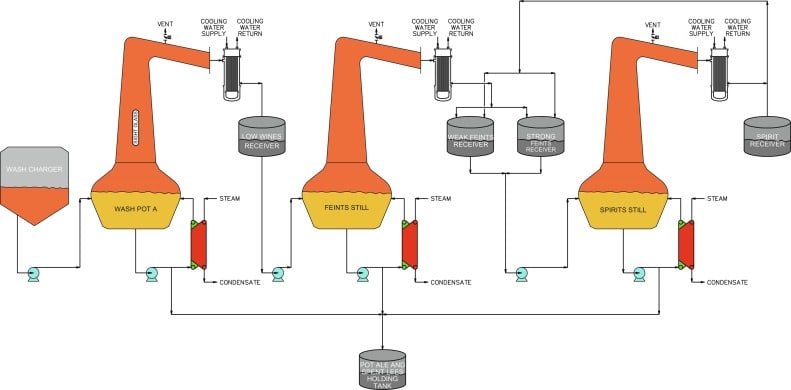

- First Distillation: The wash is transferred to the pot still for the first distillation, known as the “wash distillation.” This process separates alcohol from water and other components, producing a liquid called “low wines.”

- Second Distillation: The low wines undergo a second distillation in a smaller pot still, known as the “spirit still.” This step further refines the alcohol, separating the “heads,” “hearts,” and “tails.” The hearts, which are the most desirable portion, become the new-make spirit.

- Maturation: The new-make spirit is then aged in barrels, where it develops its flavor and character over time, ultimately becoming the Texas whiskey we know and love.

Modern Methods

While traditional methods remain vital, modern techniques have also made significant contributions to the production of Texas whiskey, incorporating advanced technology and innovative practices.

Column Stills

Column stills, also known as continuous stills, represent a significant advancement in distillation technology. Unlike pot stills, which operate in batches, column stills can run continuously, allowing for larger-scale production and increased efficiency.

Column stills consist of a series of vertically arranged plates, where the wash is introduced at the top and steam is introduced at the bottom. As the wash descends through the plates, the steam rises, causing the alcohol to vaporize and separate from the water and other components. This process results in a high-proof distillate, which can then be further refined and aged to produce whiskey.

Many Texas distilleries utilize column stills to meet the growing demand for their products, ensuring consistency and quality on a larger scale. The ability to produce whiskey continuously without sacrificing quality has made column stills a popular choice in the industry.

Technological Innovations

In addition to column stills, technological innovations have further enhanced the distillation process in Texas whiskey production. Modern distilleries employ advanced monitoring systems and automated controls to ensure precision and consistency throughout the process.

For example, temperature and pressure sensors are used to maintain optimal conditions during fermentation and distillation, preventing variations that could affect the final product’s quality. Additionally, computer-controlled systems allow distillers to fine-tune every aspect of the process, from grain selection to aging, ensuring each batch meets the distillery’s high standards.

These technological advancements have not only improved efficiency but also allowed for greater experimentation and innovation, leading to new and exciting expressions of Texas whiskey.

Unique Techniques

Texas distilleries have developed unique techniques that set their whiskey apart, leveraging the state’s distinctive environment and creative approaches to production.

Texas-Specific Methods

One of the defining characteristics of Texas whiskey is the influence of the state’s climate on the aging process. The hot, dry conditions in Texas accelerate the interaction between the whiskey and the barrel, resulting in a faster maturation process compared to more temperate regions.

This accelerated aging imparts rich, robust flavors to the whiskey, often with pronounced notes of caramel, vanilla, and oak. Some distilleries even employ techniques such as “heat cycling,” where barrels are moved between different temperature-controlled environments to enhance the maturation process further.

Additionally, Texas distilleries often use locally sourced grains and water, adding a regional terroir to their products. The unique combination of climate, ingredients, and innovative practices creates a distinct flavor profile that sets Texas whiskey apart from its counterparts.

Distillery Innovations

Texas distilleries are known for their spirit of innovation, continually pushing the boundaries of whiskey production. This creativity has led to the development of new techniques and expressions that showcase the versatility of Texas whiskey.

One such innovation is the use of alternative aging vessels. While traditional oak barrels remain the standard, some distilleries experiment with different types of wood, such as mesquite or pecan, to impart unique flavors to their whiskey. These alternative woods can add smoky, nutty, or spicy notes, creating a one-of-a-kind tasting experience.

Another area of innovation is the exploration of different grain combinations. While corn is the primary grain used in most Texas whiskeys, some distilleries incorporate unconventional grains like blue corn, wheat, or triticale to create distinctive flavor profiles. These experimental approaches result in a diverse range of Texas whiskeys, each with its unique character and appeal.

Furthermore, Texas distilleries often engage in collaborations and limited-edition releases, partnering with breweries, wineries, or other spirits producers to create unique blends and finishes. These collaborations not only highlight the creativity and versatility of Texas whiskey but also offer consumers exciting new options to explore.

FAQs

Conclusion

The distillation techniques used in Texas whiskey production combine traditional methods with modern innovations and unique regional practices. From the use of copper pot stills to advanced column stills and the influence of Texas’s climate, each step in the process contributes to the distinctive character of Texas whiskey. The spirit of innovation and creativity found in Texas distilleries ensures that the state’s whiskey continues to stand out in the world of spirits, offering a diverse and exciting range of flavors for enthusiasts to explore.

Disclosure: Our blog contains affiliate links to products. We may receive a commission for purchases made through these links. However, this does not impact our reviews and comparisons. We try our best to keep things fair and balanced, in order to help you make the best choice for you.