The Production Process of Texas Whiskey

Texas whiskey has gained a reputation for its unique flavors and high-quality production methods. The journey from raw ingredients to a finished bottle of Texas whiskey is both an art and a science, involving several carefully controlled steps. This article delves into the detailed Production Process of Texas Whiskey, highlighting each critical stage that contributes to the distinct character.

Ingredients

Types of Grains

The foundation of any great whiskey starts with its grains. In Texas, distillers often use a blend of corn, rye, barley, and wheat, each contributing unique flavors and characteristics to the final product. Corn is the primary grain in many Texas whiskeys, lending sweetness and body. Rye adds a spicy, robust flavor, while barley introduces maltiness and helps with the fermentation process due to its high enzyme content. Wheat, used in some recipes, brings a softer, smoother profile to the whiskey.

Selecting the right type of grains is crucial, as each type imparts specific attributes to the whiskey. The quality of the grains, their origin, and the way they are processed can all affect the final product. Texas distilleries often source their grains locally, taking advantage of the state’s rich agricultural heritage. By using locally grown grains, distillers can ensure freshness and support local farmers, contributing to the distinct regional character of their whiskey.

Water Sources

Water plays a crucial role in whiskey production, influencing the flavor and overall quality. Texas distillers often source their water from local springs, rivers, or aquifers, each imparting its mineral profile to the whiskey. The purity and mineral content of the water can significantly affect the taste, making it a vital ingredient in the production process. Some distilleries take pride in using water with specific characteristics that complement their unique whiskey styles.

In addition to its mineral content, the source of water can affect the whiskey’s mouthfeel and clarity. For example, water with high levels of calcium can create a smoother, creamier texture, while water with a balanced mineral content can enhance the whiskey’s complexity. Texas distilleries often invest in advanced water filtration and treatment systems to ensure they have the ideal water profile for their whiskey production.

Fermentation

Yeast Strains

Yeast is essential for converting the sugars in grains into alcohol during fermentation. The choice of yeast strain can have a significant impact on the flavor profile of the whiskey. Texas distilleries often use proprietary yeast strains, carefully selected and cultivated to produce desired esters and congeners that contribute to the whiskey’s complexity and aroma. Some distilleries might also use wild yeast strains native to Texas, adding a unique regional character to their whiskey.

The fermentation process begins with the preparation of the mash, a mixture of water and milled grains. Yeast is then added to the mash, where it starts to consume the sugars and produce alcohol and carbon dioxide. This process can take several days to complete, during which time the mash transforms into a mixture known as “wash,” containing about 6-10% alcohol by volume.

Fermentation Techniques

Fermentation typically takes place in large, temperature-controlled tanks. The mash, consisting of water and milled grains, is mixed with yeast and allowed to ferment for several days. During this time, the yeast converts the sugars into alcohol, producing a mixture known as “wash.” Texas distilleries may use open or closed fermentation techniques. Open fermentation, in wooden or stainless steel vats, can introduce local wild yeast and bacteria, adding unique flavors. Closed fermentation, on the other hand, offers more control over the process, ensuring consistency and preventing contamination.

The temperature and duration of fermentation can significantly affect the final flavor profile of the whiskey. Higher fermentation temperatures tend to produce more esters and fruity flavors, while lower temperatures result in a cleaner, crisper taste. Texas distilleries carefully monitor and adjust fermentation parameters to achieve their desired flavor outcomes.

Distillation

Copper Pot Stills

Distillation is the process of separating alcohol from the wash through heating and condensation. Many Texas whiskey producers use traditional copper pot stills, which are favored for their ability to enhance flavors and remove unwanted impurities. Copper reacts with sulfur compounds, producing a smoother, more refined spirit. The shape and size of the pot still can also influence the final product, with each distillery often having its unique design.

Copper pot stills are typically used for batch distillation, where the wash is heated until the alcohol vaporizes. The vapor rises through the neck of the still and condenses back into liquid form in a separate chamber. This process is usually repeated multiple times, known as “double distillation,” to increase the alcohol content and refine the flavor. The use of copper pot stills is a traditional method that has been passed down through generations, preserving the artisanal quality of Texas whiskey.

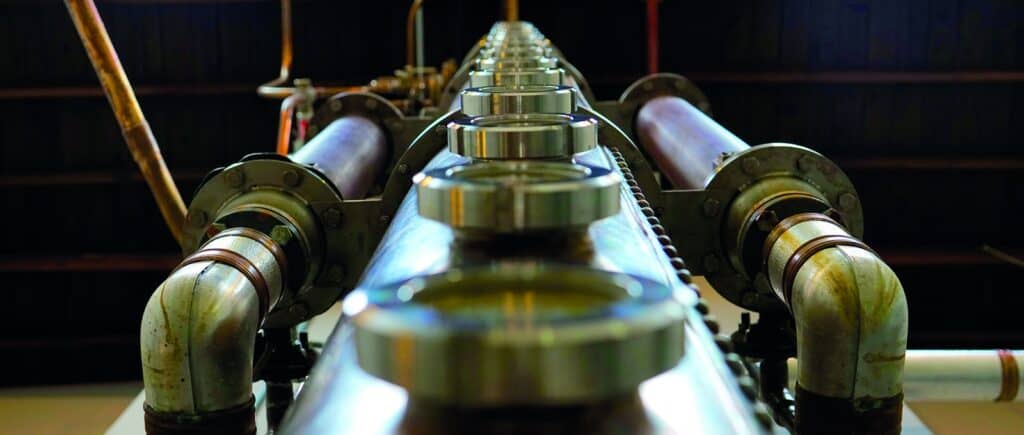

Column Stills

Some Texas distilleries employ column stills, which allow for continuous distillation and higher efficiency. Column stills consist of a series of stacked plates, where the wash is heated and vaporized. As the vapor rises through the column, it condenses on the plates, gradually increasing in alcohol concentration. Column stills can produce a higher proof spirit and are often used in conjunction with pot stills to achieve the desired flavor profile.

Column stills are particularly effective for producing large quantities of whiskey with consistent quality. The continuous nature of column distillation allows for precise control over the distillation process, resulting in a cleaner spirit with fewer impurities. Texas distilleries may use column stills to produce the base spirit, which is then refined and blended with pot-distilled whiskey to create a balanced and complex final product.

Aging Process

Barrel Types

Aging is a critical step that imparts depth and character to Texas whiskey. Distilleries typically use new charred American oak barrels, which contribute rich flavors of vanilla, caramel, and spice. The charring process creates a layer of charcoal inside the barrel that filters the whiskey and enhances its complexity. Some distilleries may also experiment with different types of oak, such as French or Hungarian, or use barrels that previously held other spirits, like sherry or bourbon, to add unique flavor notes.

The choice of barrel can significantly influence the whiskey’s flavor, aroma, and color. New charred American oak barrels are commonly used because they impart robust, bold flavors and a deep amber hue. However, using barrels that previously aged other spirits can introduce additional layers of complexity, such as fruity or nutty notes from sherry casks or sweet, vanilla tones from bourbon barrels. Texas distilleries often experiment with different barrel types to create unique and innovative expressions of their whiskey.

Aging Conditions

The aging process is influenced by Texas’ unique climate, which can vary significantly from one region to another. High temperatures and fluctuations can accelerate the interaction between the whiskey and the wood, often leading to a more intense flavor profile in a shorter amount of time. Distilleries carefully monitor temperature, humidity, and air circulation in their aging warehouses to ensure optimal maturation. The location of the barrels within the warehouse can also affect the aging process, with barrels at higher levels typically aging faster due to higher temperatures.

Texas’ climate poses both challenges and opportunities for whiskey aging. The hot summers and mild winters create a dynamic environment where the whiskey expands and contracts within the barrels, intensifying the extraction of flavors from the wood. This rapid aging process can produce richly flavored whiskey in a shorter period compared to regions with cooler climates. Distilleries must carefully manage these conditions to achieve a balanced and harmonious final product.

Bottling

Bottling Process

Once the whiskey has reached its desired maturity, it is ready for bottling. The bottling process involves several steps to ensure the whiskey maintains its quality and consistency. The whiskey is often filtered to remove any particulate matter, which could affect its clarity and presentation. It is then diluted with water to achieve the desired proof, as whiskey often comes out of the barrel at a higher alcohol concentration. Texas distilleries take great care during this stage to preserve the flavors developed during aging.

The bottling process is a critical final step where attention to detail is paramount. Each bottle is filled, sealed, and labeled with care, ensuring it meets the distillery’s standards for quality and presentation. Some distilleries may also include additional steps, such as chill filtration, to remove any remaining impurities and ensure the whiskey’s clarity and stability.

Quality Control

Quality control is paramount in the final stages of whiskey production. Before bottling, each batch of whiskey undergoes rigorous testing and tasting to ensure it meets the distillery’s standards. This can include sensory evaluation by expert tasters, as well as chemical analysis to check for consistency in flavor, aroma, and alcohol content. Ensuring each bottle of Texas whiskey upholds the brand’s reputation for excellence is a critical aspect of the production process.

Distilleries employ a variety of quality control measures to maintain the integrity of their whiskey. Sensory evaluation involves trained tasters assessing the whiskey’s aroma, taste, and mouthfeel to ensure it meets the desired profile. Chemical analysis can detect any off-flavors or inconsistencies that might affect the final product. By combining these techniques, Texas distilleries can ensure that every bottle of whiskey is of the highest quality.

FAQs

Conclusion

The production process of Texas whiskey is a complex and carefully managed journey that transforms raw ingredients into a refined and flavorful spirit. From selecting the finest grains and water sources to the intricacies of fermentation, distillation, aging, and bottling, each step is crucial in creating the distinct character of Texas whiskey.

The combination of traditional techniques and innovative practices, along with Texas’ unique climate, contributes to the exceptional quality and unique flavor profiles that define Texas whiskey. Whether you’re a whiskey enthusiast or new to the spirit, understanding this process deepens the appreciation for the craftsmanship behind every bottle.