Production Process of American Whiskey and Bourbon

Welcome, fellow whiskey enthusiasts! Today, we’re diving deep into the world of American whiskey and bourbon. From the grains in the mash to the aging barrels, every step in the production process contributes to the unique flavor profiles that whiskey lovers adore. Whether you’re a seasoned connoisseur or a curious novice, understanding how these spirits are crafted will enhance your appreciation for every sip. So, grab a glass, sit back, and let’s explore the fascinating journey of American whiskey and bourbon production!

Ingredients Used

The production of American whiskey and bourbon is deeply rooted in the selection and preparation of specific ingredients. These components are critical to creating the unique flavors and characteristics that distinguish each variety.

Grains and Other Ingredients

Grains form the backbone of whiskey and bourbon production. They are chosen carefully to ensure that the final product meets the traditional standards and desired flavor profiles.

Corn, Rye, Barley, and Wheat

In the production of bourbon, corn is the dominant grain, comprising at least 51% of the mash bill. This high corn content gives bourbon its signature sweetness and smoothness. Rye, barley, and wheat are also commonly used grains. Rye adds a spicy and robust flavor, barley contributes to the malting process which introduces enzymes necessary for fermentation, and wheat offers a softer, mellower taste.

Corn’s sweetness balances out the more aggressive flavors of rye, creating a well-rounded flavor profile. In some recipes, a higher percentage of rye can give the bourbon a more pronounced spiciness, while more wheat can make it even smoother. The balance of these grains is carefully calculated to achieve the desired taste.

Water and Its Importance

Water is another vital ingredient in whiskey and bourbon production. The quality of water can significantly influence the final product. Distilleries often source water from natural springs or other pure sources, ensuring it is free of impurities that could alter the taste. The mineral content of the water can also affect the fermentation process and the final flavor of the spirit.

The pH level and mineral content of the water play crucial roles in the fermentation process. For instance, water with a high mineral content can enhance the efficiency of the fermentation process, leading to a richer, more robust flavor. Distilleries often pride themselves on the unique qualities of their water sources, which can contribute to the distinctive character of their products.

Distillation Methods

Distillation is a critical stage in the production of American whiskey and bourbon. This process concentrates the alcohol content and refines the flavors.

Distillation Techniques in American Whiskey

American whiskey distillation typically involves the use of a pot still or a column still. Pot stills are traditional and operate in batches, allowing for greater control over the final product. Column stills, on the other hand, are more efficient and can produce higher volumes of spirit in a continuous process. Both methods are used depending on the desired flavor profile and production scale.

Pot stills are renowned for producing spirits with complex, layered flavors. The batch process allows distillers to make adjustments and fine-tune each batch, resulting in a product with distinct character. Column stills, also known as continuous stills, offer a more streamlined production process, which is advantageous for larger operations. They can produce a high-proof spirit in a single run, making them ideal for large-scale production.

Distillation Techniques in Bourbon

Bourbon distillation also employs pot stills and column stills. The choice between these methods depends on the distiller’s goals. Pot stills are favored for producing small batches with distinct flavors, while column stills are used for larger-scale production. The distillation process for bourbon must ensure that the spirit is distilled to no more than 160 proof (80% alcohol by volume) to retain the grain’s character and flavors.

The distillation process for bourbon is designed to preserve the integrity of the grains used in the mash bill. By distilling to a lower proof, more of the grain’s natural flavors are retained, contributing to the rich, complex profile that bourbon is known for. The distillate, known as “white dog,” is clear and strong, with a potent mix of flavors that will mellow and develop further during the aging process.

Aging Process

The aging process is what transforms distilled spirit into whiskey or bourbon, imbuing it with rich flavors and complexity.

Aging in Different Types of Barrels

Barrel aging is an essential part of the whiskey and bourbon production process. The type of barrel used can dramatically impact the taste, aroma, and color of the final product.

New Charred Oak Barrels

Bourbon must be aged in new charred oak barrels. These barrels impart significant flavor and color to the spirit. The charring process creates a layer of char that interacts with the whiskey, adding notes of caramel, vanilla, and smoke. The law mandates that bourbon must be aged for a minimum of two years to be classified as straight bourbon, although many are aged longer for deeper, more complex flavors.

The interaction between the whiskey and the charred oak is a fascinating chemical process. As the whiskey expands and contracts with temperature changes, it moves in and out of the wood, extracting compounds like vanillin and tannins. These compounds contribute to the flavor, aroma, and color of the final product. The length of aging can vary, with some bourbons maturing for many years to achieve a richer, more nuanced profile.

Reused Barrels

While bourbon requires new barrels, other types of American whiskey can be aged in reused barrels. These barrels may have previously held bourbon, wine, or other spirits, adding unique characteristics to the whiskey. The reuse of barrels allows for experimentation and the creation of distinctive flavor profiles that vary from one distillery to another.

Reused barrels offer a wealth of possibilities for flavor innovation. For instance, whiskey aged in barrels that previously held sherry or port can take on some of the fruit and spice notes from these wines. This method of aging can result in a complex, layered spirit that offers a different experience from traditionally aged whiskeys. Distillers often experiment with various types of barrels to create unique, limited-edition products.

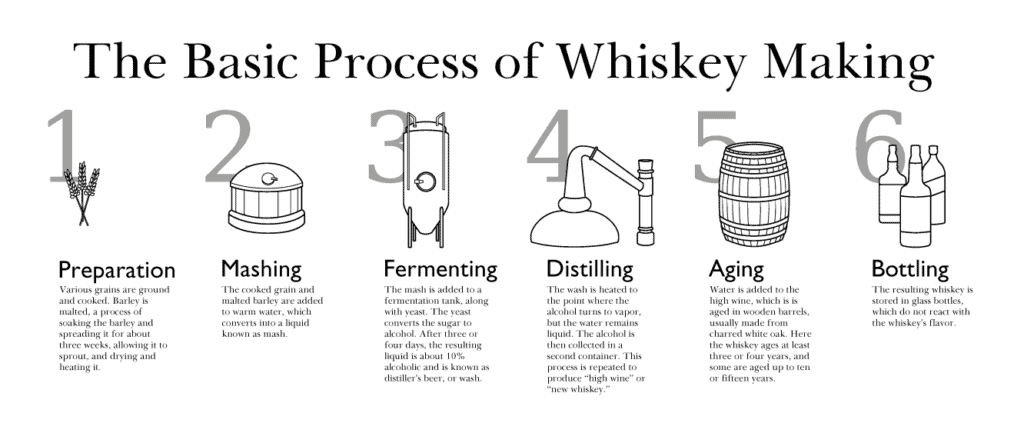

Fermentation Process

Before distillation, the fermentation process is a crucial step in converting the grains into alcohol.

Mash Preparation

The process begins with the preparation of the mash. Grains are ground and mixed with water to create a mash, which is then cooked to break down the starches into fermentable sugars.

Yeast Addition and Fermentation

Yeast is then added to the mash to begin fermentation. The type of yeast used can significantly influence the flavor of the final product. Fermentation typically lasts from three to seven days, during which the yeast converts the sugars into alcohol and carbon dioxide.

Temperature Control

Maintaining the correct temperature during fermentation is critical. Too high a temperature can kill the yeast or produce unwanted flavors, while too low a temperature can slow down the fermentation process.

Maturation and Bottling

After aging, the whiskey or bourbon undergoes several additional processes before it reaches the bottle.

Blending and Proofing

Once the aging process is complete, the whiskey or bourbon is often blended to achieve a consistent flavor profile. Water is added to reduce the alcohol content to the desired proof, typically around 40-50% ABV.

Filtering and Bottling

The final product is then filtered to remove any impurities before being bottled. Some distilleries may use a chill filtration process, while others may opt for non-chill filtration to preserve more of the natural oils and flavors.

Quality Control

Quality control is paramount throughout the entire production process. Distilleries perform rigorous testing and tasting to ensure that each batch meets their standards and maintains the brand’s reputation.

- Innovations in Whiskey and Bourbon Production: The whiskey and bourbon industry continues to evolve, with new techniques and technologies enhancing the production process.

- Sustainable Practices: Many distilleries are adopting sustainable practices to reduce their environmental impact. This includes sourcing local ingredients, using renewable energy, and implementing waste-reduction measures.

- Experimental Aging Techniques: Distillers are also experimenting with new aging techniques, such as using smaller barrels for quicker aging or adding flavor through the use of alternative woods and barrel finishes.

- Technological Advances: Advances in technology are improving efficiency and quality control in the production process. From precision temperature control during fermentation to advanced filtration systems, these innovations are helping distilleries produce better spirits.

Disclosure: Our blog contains affiliate links to products. We may receive a commission for purchases made through these links. However, this does not impact our reviews and comparisons. We try our best to keep things fair and balanced, in order to help you make the best choice for you.